brinell hardness testing|brinell hardness testing method : trader Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels. This feature contributed to its early adoption over competing hardness tests. webTalkdesk Click-to-Call extension disabled automatically Related Release Notes & Product Notices. Talkdesk may have patents, patent applications, trademarks, copyrights, or other intellectual property rights covering subject matter herein. Except as expressly provided in any written license agreement from Talkdesk, the furnishing of this .

{plog:ftitle_list}

WEB1. Entenda o que é hackear. Falando em termos amplos, hackear se refere a um leque de técnicas utilizadas para se comprometer ou obter acesso a um sistema digital, seja um computador, um dispositivo móvel ou uma rede. Hackear envolve diversas habilidades específicas — algumas muito técnicas, outras mais psicológicas.

Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels. This feature contributed to its early adoption over competing hardness tests.The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .

Hardness testing is a crucial method in materials science and engineering to evaluate the strength and durability of materials, with Vickers and Brinell being two of the most commonly .Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading . Significance and Use 4.1 The Brinell hardness test is an indentation hardness test that can provide useful information about metallic materials. This information may .

Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell .Brinell hardness is a unit of measurement that indicates the hardness of a material. It is measured using the Brinell hardness method, for which a hardmetal ball is pressed into the material. The size of the resulting .

In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find . The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to .

Brinell Hardness Tester is a rapid and accurate method to determine hardness value with ASTM E-10 compliance. Applying loads of up to 3.000 kgf, the Brinell test is ideal for castings and forgings. Skip to main content [email protected] 1-877-884-8378 .

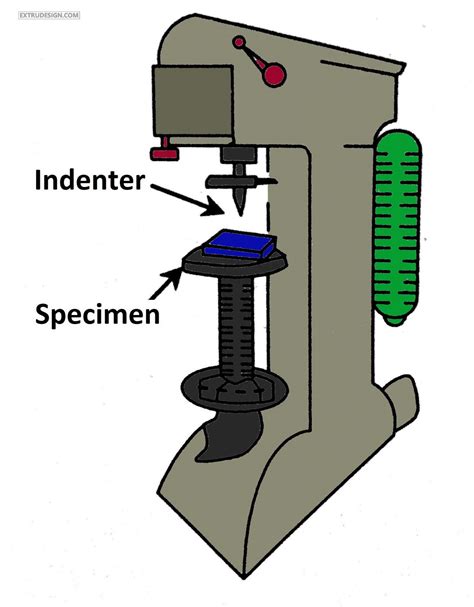

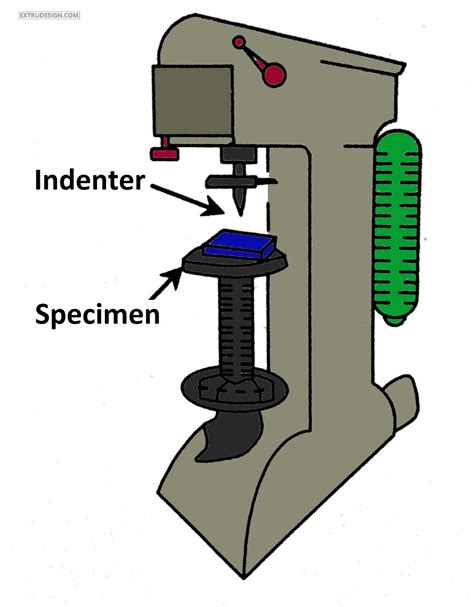

In metallurgy: Testing mechanical properties .oldest of such tests, the Brinell hardness test, uses a 10-millimetre-diameter ball and a 3,000-kilogram load. Brinell hardness values correlate well with UTS.Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information about their hardness, toughness, and suitability for specific applications by subjecting materials to controlled indentation.In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter.The Newage KB Series is a popular, manually-controlled Brinell hardness tester that meets ASTM E-110. This lightweight, portable tester is ideal for virtually any size or shape of metal specimen. Keep Reading. Pin Brinell Hardness Tester. The Pin Brinell is a cost effective instrument, which uses a calibrated shear pin to control the amount of .

The Wilson BH3000 Brinell Hardness Tester stands as a robust Brinell hardness tester, boasting a wide range from 62.5 kgf to 3000 kgf. Crafted with rugged construction for resilience in challenging environments, this reliable hardness tester blends high rigidity and closed-loop load cell technology to ensure precise and secure load applications.

Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide).The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.

The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number. Brinell hardness of some materials. Material. Brinell Hardness. Copper. 35 HB. Aluminum (pure) 15 HB. AW-6060 aluminum.

The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for achieving the bulk or macro-hardness of a material, particularly those materials with heterogeneous structures.

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Characteristics and Application of Brinell Hardness. This method is well .The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to .

The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. The diameter of the resulting permanent impression in the tested metal is measured and the Brinell Hardness .Brinell Hardness Test. The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test uses a desktop machine to apply a specified load to a hardened sphere of a specified diameter. The Brinell hardness number, or simply .3.1.4 Brinell hardness test—an indentation hardness test using a verified machine to force an indenter (tungsten carbide ball with diameter D), under specified conditions, into the surface of the material under test. The diameter of the resulting indentation d is .

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter .The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as:These ball indenters meet ISO 6506 and ASTM E10 standards for Brinell hardness testing. The shank diameter is a standard size for bench-top Brinell hardness testers. 2. 5 mm diameter ball indenters are a good choice when testing material with limited space for measuring or material that is thin and may fracture under heavy loads.

brinell hardness testing procedure

King Portable Brinell Hardness Testers are the most reliable, easy to use and affordable portable Brinell testers that are certified and calibrated per ASTM E-10 standards and the ONLY portable Brinell testers on the market that are accurate to within 1% with traceability to NIST.

Portable Brinell Hardness Tester KH180,can be Freely Converted to All Hardness Systems (HL, HB, HRB, HRC, HRA, HV, HS) Without Calculation. 9.00 $ 239. 00. List: 9.00 9.00. FREE delivery Wed, Aug 28 . Only 16 left in stock - order soon. Add to cart-Remove.A full selection of hardness testers, testing machines, testing equipment and accessories for Vickers, Knoop, Brinell and Rockwell hardness testing from Struers, the world’s leading materialographic and metallographic equipment supplier.Our webshop offers online sales of accessories such as hardness test blocks, anvils, and indenters for Rockwell, Brinell, Vickers, Knoop hardness testing at an affordable price. Visit the webshop here. RECENT NEWS. Acquire the most accurate and easy way to .

saliva home collect test kit drop off

saliva test drop off

WEBSpiele die besten Slots in der DrückGlück Spielothek online – am besten mit Bonus! Wir wollen dir die ausführliche DrückGlück Spielothek Bewertung auf dieser Seite präsentieren. DrückGlück, das seit 2015 existiert, ist ein außergewöhnlicher Glücksspielanbieter. Betrieben von der Skill On Net Ltd, befindet sich dessen Hauptsitz im .

brinell hardness testing|brinell hardness testing method